Copa America, giải đấu bóng đá danh giá của Nam Mỹ, luôn là tâm điểm của sự chú ý. Vậy Copa America mấy năm 1 lần? Câu hỏi này không chỉ thu hút người hâm mộ mà còn là chủ đề thảo luận sôi nổi trong giới chuyên môn. Mục lục1 Giới thiệu về Copa […]

Trong bóng đá, hiệp phụ là giai đoạn quan trọng quyết định kết quả cuối cùng của trận đấu loại trực tiếp. Vậy hiệp phụ bóng đá bao nhiêu phút và những quy định nào điều chỉnh thời gian này? Mục lục1 Tại sao cần hiệp phụ trong bóng đá2 Hiệp phụ bóng đá bao […]

Bạn đã bao giờ tự hỏi WC viết tắt của từ gì? WC là viết tắt của tên giải đấu bóng đá lớn nhất hành tinh. Hãy cùng khám phá ý nghĩa thực sự đằng sau hai chữ cái viết tắt WC này qua bài viết dưới đây. Mục lục1 WC viết tắt của từ […]

TÌm hiểu về fan Chelsea gọi là gì không chỉ là câu hỏi của riêng người hâm mộ bóng đá Anh. Đó còn là chủ đề thu hút sự quan tâm của bất kỳ ai yêu mến bộ môn túc cầu, đặc biệt là những người yêu mến màu xanh của The Blues. Mục lục1 […]

Đã ba giờ bạn thắc mắc fan Liverpool gọi là gì? Câu lạc bộ bóng đá này không chỉ nổi tiếng với lịch sử lâu đời và thành tích đáng nể, mà còn có một cộng đồng người hâm mộ đặc biệt, với một danh xưng độc đáo. Hãy cùng khám phá và hiểu rõ […]

Bạn đã bao giờ tự hỏi fan MU gọi là gì? Trong thế giới bóng đá nhiều màu sắc, người hâm mộ Manchester United không chỉ đơn thuần là những người yêu mến đội bóng. Họ có những cách xưng hô đặc biệt, thể hiện niềm tự hào và tình yêu sâu đậm với Quỷ […]

Bạn đã bao giờ tự hỏi Vua bóng đá là ai? Câu hỏi này không thể làm khó người hâm mộ bóng đá lâu năm. Trong bài viết này, chúng ta sẽ khám phá cuộc đời và sự nghiệp của Pele, người được mệnh danh là Vua bóng đá và đã định hình và thay […]

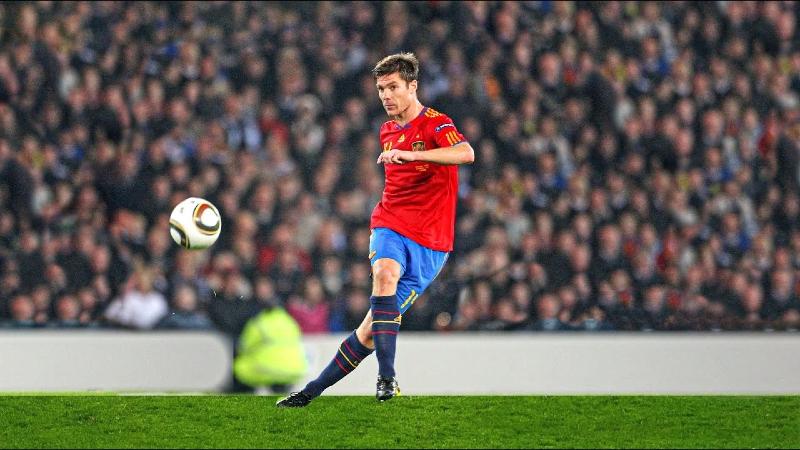

Sút bóng căng không chỉ là kỹ năng quan trọng trên sân cỏ bóng đá mà còn là nghệ thuật đòi hỏi sự chính xác và mạnh mẽ. Bài viết này sẽ đưa bạn tìm hiểu cách sút bóng căng, từ những nguyên tắc cơ bản đến những bí quyết giúp bạn thực hiện những […]

Kỹ thuật chuyền bóng là nền tảng quan trọng, quyết định sự linh hoạt và mượt mà của lối chơi của mỗi đội bóng. Một đường chuyền tốt có thể mở ra pha tấn công nguy hiểm, giúp đội nhà giành lợi thế. Mục lục1 Tầm quan trọng của kỹ thuật chuyền bóng2 Kỹ thuật […]

Bạn đang thắc mắc đá phạt trực tiếp là gì? Đây là một trong những tình huống thú vị bậc nhất trên sân cỏ, nơi cầu thủ có cơ hội trực tiếp ghi bàn từ một khoảng cách nhất định mà không bị cản trở bởi hàng phòng ngự đối phương. Mục lục1 Định nghĩa […]

- 1

- 2